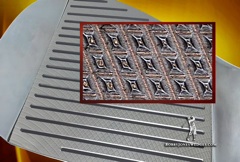

| The aerospace steel alloy Carpenter 440XH face materialused on the Bobby Jones Pelz Series Wedge is a remarkably wear-resistant metal alloy (often used in industrial bearing assemblies and critical valve components) will maintain both face friction and groove integrity far longer than conventional wedges, thus providing consistently high backspin longevity. With new USGA regulations on the horizon, wedge durability will be more important than ever for maintaining shot trajectory and control. The Carpenter 440XH material on the Bobby Jones Wedges is milled to a USGA-conforming texture of 180 micro-inches, creating a face texture and edge-groove radius perfect for consistent shot making. Many golfers do not realize that backspin longevity is so fleeting that tour professionals replace their wedges often throughout the golf season to keep ball control and shot performance at the highest possible level. "These enduring wedges will help golfers hit better scoring game shots, control their wedge distances to tighter tolerances, and consistently shoot lower scores," said Pelz. Using a proprietary design technique, Bobby Jones Pelz Wedges provide the perfect combination of soft-feeling shots and extremely low face wear to produce a superior-performing wedge, season after season. By applying heat and pressure to a special structural bonding membrane, Ortiz facilitates the release of an epoxy resin, which upon cooling creates a bond between the club's stainless body and face material that is stronger than welding. Upon curing, the membrane returns to its slightly spongy state, thus creating a soft forged-like feel to each shot.

|